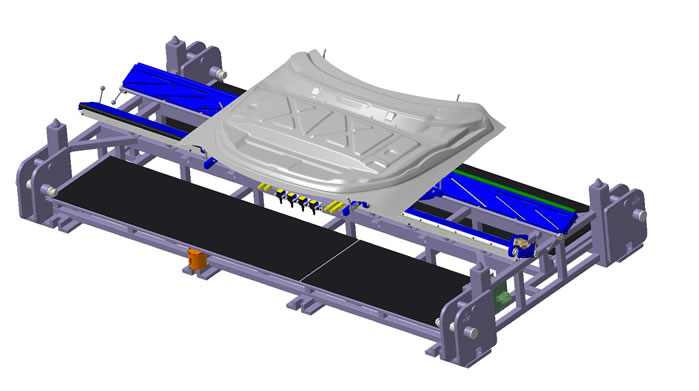

BLUE-SLICE TOOLING

Blueslice cad

Norgren Automation Solutions Blue-Slice nesting tooling system provides a completely configurable product tailored specifically to your needs. The Blue-Slice is compatible with existing lower tooling “trees” while providing an increase in productivity.

Key Features

Faster Setup – The operator needs only two trips to the cart per station to move the blue slices to the bar instead of 3-4 trips for old fashion tooling

Easier Setup – The slices are held together in order, so the operator can place them where they need to go faster and easier

Coded Locations – Each blade is coded so they can’t be placed in the wrong locations. This will reduce setup time and crashes due to misplaced tooling

An End to Lost Tooling – Because all the blades are held together, lost tooling is much less likely, a problem that happens often with current tooling

Advanced Ergonomics – The carriers are simple to lift and load as opposed to old fashioned tooling, which could be large and difficult to handle

Limited Floor Space? – Because the blades are smaller, a new cart design will be able to hold twice as much tooling, allowing cart usage to be cut in half

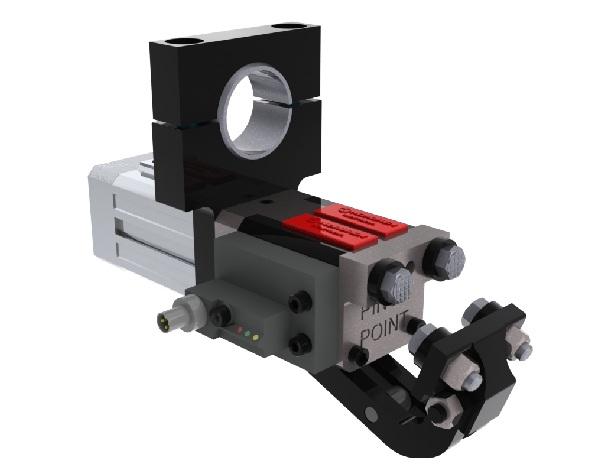

GC4 GRIPPER

GC4 large

Features

40mm Cylinder Bore

Modular configuration

Rotary gripper head for unlimited adjustment

Flange and orbital rod mounts

Field changeable jaw openings

Field changeable single or double point tips

Fixed or adjustable tip inserts

Optional edge guards

Optional side plate proximity sensing

Optional magnetic reed cylinder sensing

Multiple head type options

Technical Data

Fluid: Compressed air

Minimum Air pressure: 2.76 bar (40 psi)

Maximum Air pressure: 8 bar (116 psi)

Operating temperature: -4°C (25°F) to 77°C (170°F)

Air consumption: 32mm: 1.37in.3 or 22.52cm3

Air filtration: 40 Micron

SERIES IOT SWIVEL ARMS

Vacuum cup and accessory mounting arm

Compatible with most brands of venturi or vacuum cup mounting devices

Infinite length and rotational position adjustment over the available adjustment range

For compatible accessories, please see series TL and TP Vacuum Cup Mount / Venturi

RADIAL CAM

The Radial Cam from Norgren Automation Solutions provides a new direction in metal forming.

Eliminates by-pass flanging for geometry in same plane motions

Contacts class-A surfaces completely at initial contact

Improves panel quality, less scrap in production

Reduces die tryout times

Adjust timing easily in the tryout press

No machining required for timing adjustments

Smaller die footprint

Less maintenance in production

Makes a longer flange at notch

Built in CAD model