K-TEC 155 S

Clamping Unit

kN Clamping Force

mm Tie Bar Clearance (H x V)

mm Clamping Platens Size (H x V)

mm Mold Opening Stroke

mm Distance Between Platens max.

mm Mold Installation Height min./max.

kg Mold Weight max. (movin xed)

kN Opening Force

kN Ejector Force

mm Ejector Stroke

s – mm Dry Cyle (Euromap 6) 1)

Injection Unit

mm Screw Diameter

bar Injection Pressure max.

Stroke Volume max.

g Injected Weight max. (PS)

mm Screw Stroke

mm Unit Stroke

kN Nozzle Holding Force

Injection Rate

min -1 Screw Speed

g/s Recovery Rate 2)

L/D Active Screw Length3)

qty Number of Heating Zones

kW Total Heating Capacity

General Data

kW Total Connected Power4)

m Machine Dimensions (L x W x H)

kg Net Weight

l Oil Tank Capacity

1) Stroke = 70% Tie Bar Clearance, 70% Clamping Force 2) For PS: 10 s Cycle Time, 1,5 D Screw Stroke 3) Other L/D on Request

4) According to Ferromatik Milacr ion 5) Option

V = Vertical

H = Horizontal

PB = Piggy Back

T = Traversing

VM = Vertical Monosandwich

HM = Horizontal Monosandwich

2nd Injection Unit Optional with Position

155

1.550

500 x 500 (560 x 560) 5)

750 x 750 (810 x 830) 5)

650

950

300 / –

1.200 / 600

86

50

180

2 – 350

265 493 970

30 35 40 40 45 50 45 50 60

2.292 1.964 1.504 2.240 1.936 1.568 2.294 2.058 1.429

99 135 176 201 254 314 382 471 679

90 123 160 183 231 286 375 429 618

140 160 240

240 290 400

47 47 63

280 380 495 570 720 885 636 785 1.131

400 320 300

15 20 28 25 32 40 28 44 55

20 20 17,3 20 21,4 19,3 22 24,2 20

4 + 1 4 + 1 4 + 1

6,4 10,4 10,4 12,7 14,5 14,5 16,1 18,8 18,8

155 – 265 155 – 493 155 – 970

34 37 37 39 40 40 41 43 43

5,52 x 1,73 x 2,36 5,52 x 1,73 x 2,36 6,39 x 1,73 x 2,36

7.600 7.800 8.200

480 480 480

2nd Injection Unit Optional

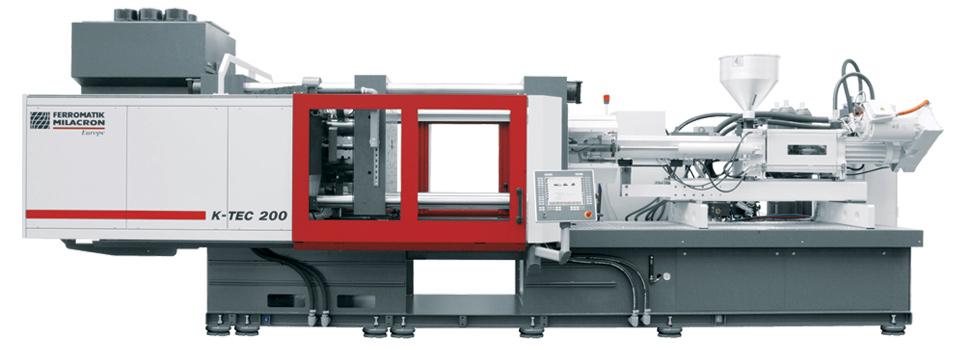

K-TEC 175 S / K-TEC 200 S

175 / 200

1.750 / 2.000

560 x 560 (630 x 630, 750 x 750) 5)

830 x 935 (970 x 1.035, 1.110 x 1.165) 5)

750

1.045

295 / –

1.450 / 700

119 / 134

85

1,6 – 392

493 1000 1650

40 45 50 50 60 60 70

2.240 1.936 1.568 2.268 1.575 2.144 1.575

201 254 314 441 636 763 1.039

183 231 286 401 579 694 946

160 225 270

290 525 525

47 63 115

570 720 885 1.480 2.000 1.480 2.000

330 320 275

25 32 40 52 65 60 67

20 21,4 19,3 22 18,3 22 18,6

12,7 14,5 14,5 18,2 18,2 22,7 22,7

175 / 200 – 493 175 / 200 – 1000 175 / 200 – 1650

46 47 47 50 71

6,85 x 2,04 x 2,55 6,87 x 2,04 x 2,55 7,30 x 2,04 x 2,55

12.000 13.000 13.800

500 500 500

K-TEC 250 S / K-TEC 275 S

250 / 275

2.500 / 2.750

630 x 630 (750 x 750, 825 x 825) 5)

970 x 1035 (1.110 x 1.165, 1.110 x 1.195) 5)

850

1.195

345 / –

2.400 / 1.150

144 / 163

200

1,8 – 441

1000 1650 2650

50 60 60 70 70 80

2.268 1.575 2.144 1.575 2.175 1.665

441 636 763 1.039 1.213 1.583

401 579 694 946 1.104 1.441

225 270 315

525 525 525

63 115 115

1.480 2.000 1.480 2.000 1.550 2.000

320 275 240

52 65 60 67 73 85

22 18,3 22 18,6 22 19,3

18,2 18,2 22,7 22,7 30,7 30,7

250 / 275 – 1000 250 / 275 – 1650 250 / 275 – 2650

68 71 77

7,49 x 2,16 x 2,66 7,76 x 2,16 x 2,66 8,22 x 2,16 x 2,66

15.500 16.000 18.500

680 680 680

111 : V – H – PB – T

mm 18 25 30 mm Screw Diameter

265 : V – H – PB – T

mm 30 35 40 mm Screw Diameter

493 : V – H – PB – T – VM

mm 40 45 50 mm Screw Diameter

1000 : H – HM

mm 45 50 60 mm Screw Diameter

K-TEC 320 S / K-TEC 350 S

320 / 350

3.200 / 3.500

750 x 750 (825 x 825) 5)

1.110 x 1.165 (1.110 x 1.195) 5)

1.230

380 / –

3.000 / 1.500

179

2,1 – 525

320 / 350 – 1000 320 / 350 – 1650 320 / 350 – 2650

7,69 x 2,22 x 2,76 8,02 x 2,22 x 2,76 8,44 x 2,22 x 2,76

20.500 21.000 22.000

970 : T 1000 : H – HM

2650 : HM

mm 70 80 mm Screw Diameter

K-TEC 400 S / K-TEC 450 S

400 / 450

4.000 / 4.500

825 x 825 (900 x 900, 1.000 x 1.000) 5)

1.195 x 1.267 (1.270 x 1.345, 1.370 x 1.445) 5)

1.000

1.420

420 / –

4.000 / 2.000

181 / 205

3 – 578

1650 2650 4400

60 70 70 80 80 90 100

2.144 1.575 2.175 1.665 2.431 1.921 1.556

763 1.039 1.213 1.583 1.810 2.290 2.825

694 946 1.104 1.441 1.647 2.084 2.571

270 315 360

115 115 115

1.480 2.000 1.550 2.000 2.250 2.850 3.550

275 240 190

60 67 73 85 80 103 128

22 18,6 22 19,3 22,5 20 18

22,7 22,7 30,7 30,7 48,4 48,4 48,4

400 / 450 – 1650 400 / 450 – 2650 400 / 450 – 4400

71 77 109

8,38 x 2,33 x 3,03 8,86 x 2,33 x 3,03 9,56 x 2,33 x 3,03

26.000 27.000 30.000

1.000 1.000 1.000

2. Spritzeinheit optional mit Anordnung 2nd Injection Unit Optional with Position

Schneckendurchmesser mm 18 25 30 mm Screw Diameter

Schneckendurchmesser mm 30 35 40 mm Screw Diameter

493 : V – H – PB – T

Schneckendurchmesser mm 40 45 50 mm Screw Diameter

Schneckendurchmesser mm 45 50 60 mm Screw Diameter

Schneckendurchmesser mm 70 80 mm Screw Diameter

4400 : HM

Schneckendurchmesser mm 80 90 100 mm Screw Diameter

K-TEC 175 S / K-TEC 200 S

kN Clamping Force

mm Tie Bar Clearance (H x V)

mm Clamping Platens Size (H x V)

mm Mold Opening Stroke

mm Distance Between Platens max.

mm Mold Installation Height min./max.

kg Mold Weight max. (movin xed)

kN Opening Force

kN Ejector Force

mm Ejector Stroke

s – mm Dry Cyle (Euromap 6) 1)

Injection Unit

mm Screw Diameter

bar Injection Pressure max.

Stroke Volume max.

g Injected Weight max. (PS)

mm Screw Stroke

mm Unit Stroke

kN Nozzle Holding Force

Injection Rate

min -1 Screw Speed

g/s Recovery Rate 2)

L/D Active Screw Length3)

qty Number of Heating Zones

kW Total Heating Capacity

General Data

kW Total Connected Power4)

m Machine Dimensions (L x W x H)

kg Net Weight

l Oil Tank Capacity

1) Stroke = 70% Tie Bar Clearance, 70% Clamping Force 2) For PS: 10 s Cycle Time, 1,5 D Screw Stroke 3) Other L/D on Request

4) According to Ferromatik Milacr ion 5) Option

V = Vertical

H = Horizontal

PB = Piggy Back

T = Traversing

VM = Vertical Monosandwich

HM = Horizontal Monosandwich

2nd Injection Unit Optional with Position

175 / 200

1.750 / 2.000

560 x 560 (630 x 630, 750 x 750) 5)

830 x 935 (970 x 1.035, 1.110 x 1.165) 5)

750

1.045

295 / –

1.450 / 700

119 / 134

85

180

1,6 – 392

493 1000 1650

40 45 50 50 60 60 70

2.240 1.936 1.568 2.268 1.575 2.144 1.575

201 254 314 441 636 763 1.039

183 231 286 401 579 694 946

160 225 270

290 525 525

47 63 115

570 720 885 1.480 2.000 1.480 2.000

330 320 275

25 32 40 52 65 60 67

20 21,4 19,3 22 18,3 22 18,6

4 + 1 4 + 1 4 + 1

12,7 14,5 14,5 18,2 18,2 22,7 22,7

175 / 200 – 493 175 / 200 – 1000 175 / 200 – 1650

46 47 47 50 71

6,85 x 2,04 x 2,55 6,87 x 2,04 x 2,55 7,30 x 2,04 x 2,55

12.000 13.000 13.800

500 500 500

111 : V – H – PB – T – VM

mm 18 25 30 mm Screw Diameter

265 : V – H – PB – T – VM

mm 30 35 40 mm Screw Diameter

493 : V – H – T – VM

mm 40 45 50 mm Screw Diameter

1000 : H – HM

mm 45 50 60 mm Screw Diamete

K-TEC 250 S / K-TEC 275 S

Clamping Unit

kN Clamping Force

mm Tie Bar Clearance (H x V)

mm Clamping Platens Size (H x V)

mm Mold Opening Stroke

mm Distance Between Platens max.

mm Mold Installation Height min./max.

kg Mold Weight max. (movin xed)

kN Opening Force

kN Ejector Force

mm Ejector Stroke

s – mm Dry Cyle (Euromap 6) 1)

Injection Unit

mm Screw Diameter

bar Injection Pressure max.

Stroke Volume max.

g Injected Weight max. (PS)

mm Screw Stroke

mm Unit Stroke

kN Nozzle Holding Force

Injection Rate

min -1 Screw Speed

g/s Recovery Rate 2)

L/D Active Screw Length3)

qty Number of Heating Zones

kW Total Heating Capacity

General Data

kW Total Connected Power4)

m Machine Dimensions (L x W x H)

kg Net Weight

l Oil Tank Capacity

1) Stroke = 70% Tie Bar Clearance, 70% Clamping Force 2) For PS: 10 s Cycle Time, 1,5 D Screw Stroke 3) Other L/D on Request

4) According to Ferromatik Milacr ion 5) Option

V = Vertical

H = Horizontal

PB = Piggy Back

T = Traversing

VM = Vertical Monosandwich

HM = Horizontal Monosandwich

K-TEC 250 S / K-TEC 275 S

250 / 275

2.500 / 2.750

630 x 630 (750 x 750, 825 x 825) 5)

970 x 1035 (1.110 x 1.165, 1.110 x 1.195) 5)

850

1.195

345 / –

2.400 / 1.150

144 / 163

85

200

1,8 – 441

1000 1650 2650

50 60 60 70 70 80

2.268 1.575 2.144 1.575 2.175 1.665

441 636 763 1.039 1.213 1.583

401 579 694 946 1.104 1.441

225 270 315

525 525 525

63 115 115

1.480 2.000 1.480 2.000 1.550 2.000

320 275 240

52 65 60 67 73 85

22 18,3 22 18,6 22 19,3

4 + 1 4 + 1 4 + 1

18,2 18,2 22,7 22,7 30,7 30,7

250 / 275 – 1000 250 / 275 – 1650 250 / 275 – 2650

68 71 77

7,49 x 2,16 x 2,66 7,76 x 2,16 x 2,66 8,22 x 2,16 x 2,66

15.500 16.000 18.500

680 680 680

2nd Injection Unit Optional with Position

111 : V – H – PB – T

mm 18 25 30 mm Screw Diameter

265 : V – H – PB – T

mm 30 35 40 mm Screw Diameter

493 : V – H – PB – T – VM

mm 40 45 50 mm Screw Diameter

1000 : H – HM

mm 45 50 60 mm Screw Diameter