Auma

Actuators SA and SAR

Actuators of the SA type range for open-close duty and positioning duty are rated for class A and B or types of duty S2 – 15 min. A special version for longer running is available for the S2 – 30 min duty.

The modulating actuators of the SAR range are rated for class C or types of duty S4 – 25 %. Special versions for S4 – 50 % and S5 – 25 % are also available.

Actuators of type range SA/SAR 07.2 – SA/SAR 16.2 can be combined with various controls from simple OPEN-CLOSE control to the micro-controlled version with logging of operating data or fieldbus interface.

Details

Design features SA

Torque range from 10 Nm to 32,000 Nm

Output speeds from 4 to 180 rpm

Limit and torque sensing

Available with 3-ph AC, 1-ph AC and DC motors

Handwheel for manual operation

Design features SAR

Torque range from 15 Nm to 4,000 Nm

Modulating torque range from 15 Nm to 1,600 Nm

Max. number of starts 1,200 c/h

Output speeds from 4 to 90 rpm

Available with 3-ph AC, 1-ph AC motors

Ambient conditions

High enclosure protection

High quality corrosion protection

Wide ambient temperature ranges

Options

Intermediate position switches

Switches in tandem version

Remote position transmitter

Magnetic limit and torque Transmitter

Mechanical position indicator

Functional safety: Up to SIL 2 in selected configurations

Interfaces

Electrical connection via AUMA plug/socket connector (optionally terminals)

Cable entries in different versions

Output drive types according to ISO and DIN Standards

Combinations with worm gearboxes

By combining the multi-turn actuators SA with the worm gearboxes GS, they are turned into electric part-turn actuators for higher torque requirements. These combinations supplement the part-turn actuator ranges SQ whose torque ranges are limited to 2,400 Nm.

Design features

Torque range from 250 Nm to 675,000 Nm

Swing angles up to 100°

Operating times for 90 ° from 9 s to 392 s

adjustable end stops

self-retaining

Swing angles > 100° or multi-turn

(without end stops)

Electrical connection via AUMA plug/ socket connector (optionally terminals)

Plug cover with threads for cable glands

Output drive types according to ISO and DIN standard

Combinations with linear thrust units

To perfom linear movements, e. g. in case of globe valves, the multi-turn actuator SA can be combined with the linear thrust unit LE. In case a lever arrangement has to be operated, the linear thrust unit can be mounted on a base.

Thrusts from 4 kN to 217 kN

Strokes from 50 mm up to 500 mm

Speeds from 20 mm/min to 360 mm/min

Actuators SGC and SGCR

The “small” electric part-turn actuator range with integral controls.

All parameters are directly set at the actuator.

The controls contain switchgears, power supply unit, interface to the DCS. The component automatically switches the actuator off, once the valve end position is reached, motor overheating is detected or a torque overload has occurred.

All housing parts are made of aluminium. For this reason, the actuators are lightweight devices.

The actuators SGC are rated for class A and B or types of duty S2 – 15 min, the actuators SGCR for class C or types of duty S4 – 40%.

Documents

Design features SGC and SGCR

Torque range from 25 Nm to 1000 Nm

Swing angles 82 ° to 98 °

Operating times for 90° from 4 s to 90 s

Output speeds from 0.6 to 22 rpm

Max. 16 turns per stroke

Limit and torque seating

Variable speed, brushless Motor

Position feedback signal 4 … 20 mA or

via fieldbus interface

High shock resistance

Local controls mounted separately from the actuator

Control inputs with different voltages (DC/AC)

Potential-free signal relays for status indication

Fieldbus Interface

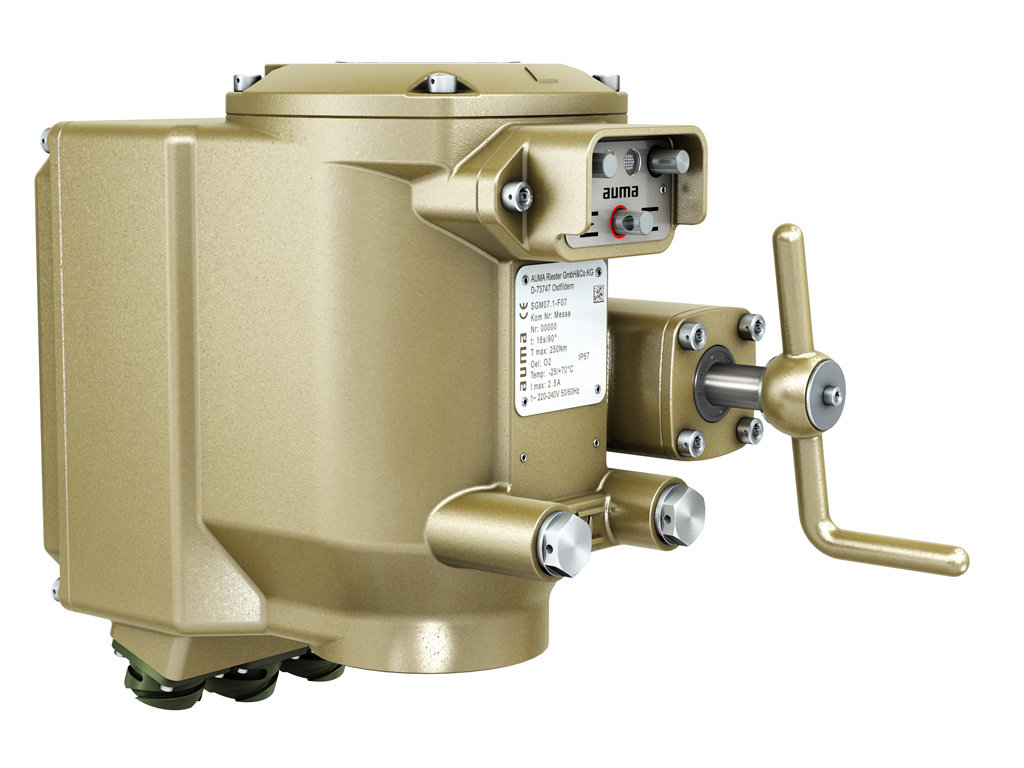

Actuators SGM and SGMR

The “small” electric part-turn actuator range with integral controls.

All housing components are made of bronze, all external screws are made of stainless steel. This ensures complete resistance against sea water even over a longer time period.

The actuators SGM are rated for class A and B or types of duty S2 – 15 min, the actuators SGMR for class C or types of duty S4 – 40%.

Design features SGM and SGMR

Position feedback signal 4 … 20 mA or via fieldbus interface