For New Batch Schedule Click Here

নতুন ব্যাচের শিডিউল জানতে এখানে ক্লিক করুন

![]() ? আপনি কি ইলেকট্রিক্যাল/ইলেকট্রনিক্স/ইলেকট্রো-মেডিক্যাল/ মেকাট্রনিক্স/মেকানিকাল/ইন্সট্রুমেন্টেশন এন্ড প্রসেস কন্ট্রোল বিভাগের শিক্ষার্থী?

? আপনি কি ইলেকট্রিক্যাল/ইলেকট্রনিক্স/ইলেকট্রো-মেডিক্যাল/ মেকাট্রনিক্স/মেকানিকাল/ইন্সট্রুমেন্টেশন এন্ড প্রসেস কন্ট্রোল বিভাগের শিক্ষার্থী?

![]() ? আপনি কি ইন্ড্রাস্ট্রিয়াল এটাচমেন্ট কোথায় করবেন ভাবছেন?

? আপনি কি ইন্ড্রাস্ট্রিয়াল এটাচমেন্ট কোথায় করবেন ভাবছেন?

![]() ? আপনি কি আপনার নিজস্ব স্কীল আরও বাড়াতে চান?

? আপনি কি আপনার নিজস্ব স্কীল আরও বাড়াতে চান?

![]() ? চাকুরির ক্ষেত্রে আপনি কি নিজেকে অন্যদের থেকে এগিয়ে রাখতে চান?

? চাকুরির ক্ষেত্রে আপনি কি নিজেকে অন্যদের থেকে এগিয়ে রাখতে চান?

![]() ? আপনি কি বিদেশে গিয়ে অটোমেশন ইঞ্জিনিয়ার হিসেবে চাকুরী করতে চান?

? আপনি কি বিদেশে গিয়ে অটোমেশন ইঞ্জিনিয়ার হিসেবে চাকুরী করতে চান?

রিলায়েন্সই একমাত্র কোম্পানী যারা সমগ্র বিশ্বের সর্বাধিক ব্যবহ্রত ৬ টি ব্রান্ডের পিএলসি এর উপর প্রশিক্ষন দিয়ে থাকে। কিন্তু অন্যান্য সাধারণ ট্রেনিং সেন্টার শুধুমাত্র একটা পিএলসির উপর ট্রেনিং দিয়ে থাকে। যারা ইন্ড্রাস্ট্রিতে জব করেন তারা অবশ্যই জানেন উপরোক্ত ৬ টা ব্রান্ডের সবগুলো পিএলসিই ইন্ড্রাস্ট্রিতে ব্যবহার হয়।

PLC Based Advanced Automation Course

(Six Branded PLC & Instrumentation)

- Introduction to PLC

- Introduction to control system

- Type of control system, PLC, Profibus, DCS, SCADA

- Power Supply, IC, SMPS

- Input Module(Digital-Analog)

- Output Module(Digital-Analog)

- Hardware configuration of PLC

- Introduction of PLC Program Language

- Languages of PLC, Ladder Concept, Programming in PLC

- Bit Logic Operation

- SIEMENS Logo PLC (Most Latest Version: 0BA8)

- Siemens PLC Hardware Description

- Program with SIEMENS PLC

- Timer function

- Counter function

- Analog Input

- PID Controller

- Message Text Display

- Analog Scaling

- Analog Comparator

- Connecting with sensor.

- Program Upload/Download

- Tricks & Tips

SIEMENS S7-1200 PLC(Most Advanced Modular Type Latest PLC)

- S7-1200 PLC Hardware Description

- Program with S7-1200 PLC

- Timer function

- Counter function

- Connecting with sensor.

- Program Upload/Download

- Tricks & Tips

MITSUBISHI PLC

- Hardware Description

- Program with MITSUBISHI PLC

- Timer function

- Counter function

- Program Upload/Download

- Tricks & Tips

Omron PLC

- Hardware Description

- Program with Omron PLC

- Timer function

- Counter function

- Program Upload/Download

- Tricks & Tips

Delta PLC

- Hardware Description

- Program with Delta PLC

- Timer function

- Counter function

- Program Upload/Download

- Tricks & Tips

LS PLC

- Hardware Description

- Program with LS PLC

- Timer function

- Counter function

- Program Upload/Download

- Tricks & Tips

Controlling Siemens PLC from Internet and Android

- Description of IP addressing, Wifi, Router, Switch

- Programming of PLC to control Machine Remotely

- Controlling PLC/Machine through Web Browser

- Controlling PLC/Machine through

- Android/iPhone

Tricks & Tips

Automation Projects

(16 Industrial Popular Automation Projects)

- Control Two Motors One By One

- Controlling Automatic Transfer Switches (ATS) for Generator and PDB

- Motor Star-Delta With PLC

- Automation of Pump With Timer

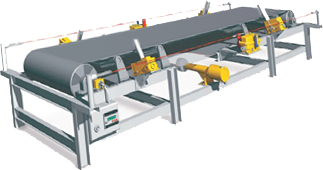

- Bottle Filling with Conveyor Belt System

- Home Automation With Automatic Light Control

- Control Garments Floor With PLC

- School Bell Control With PLC

- Batching Plant Automation

- Quiz Competition System Control With PLC

- Build Coffee Maker Machine

- Tank Automation: Reserve Tank, Overhead Tank And Underground Tank Control with Float Switch

- Heater Control With Temperature Controller

- Control Tank With Load Cell Controller And PLC

- Control Gate With Proximity Switch

- Building Electrical Safety with Circuit Breaker

Instrumentation

(14 industrial popular instrument)

- Temperature Controller

- Hardware Description

- Definition of RTD and TC

- Parameter settings

- Heater Control with Temperature Controller.

- Load Cell Module

- Hardware Description

- Load cell connection

- Analog Output measurement

- Parameter settings

- Control output with analog value.

- Load Cell

- Hardware Description

- Load cell connection

- Parameter settings

- Float Switch

- Hardware Description

- Connection Diagram

- Tank Automation Project

- Micro Switch

- Hardware Description

- Connection Diagram

- Door Automation Project

- Limit Switch

- Hardware Description

- Connection Diagram

- Automation Project

- Timer

- Hardware Description

- Parameter settings

- Automation Project

- Relay

- Hardware Description

- Connection Diagram

- Circuit Breaker: MCB, MCCB, ACB

- Hardware Description

- Connection Diagram

- Magnetic Contactor

- Hardware Description

- Connection Diagram

- MPCB(Motor Protection Circuit Breaker)

- Hardware Description

- Connection Diagram

- Proximity Sensor

- Hardware Description

- Connection Diagram

- RTD (Resistance Temperature Detector)

- Hardware Description

- Connection Diagram

- TC (Thermocouple)

- Hardware Description

- Connection Diagram

Finalization

- Over all Course Discussion

- Examination

- Certificate Distribution

VFD Course Outline

Course Objectives: Modern industrial plants rely heavily on electric motors, generally driven at variable speed called VFDs. Engineers dealing with VFDs must be well trained to be able to operate, run, troubleshoot and understand the effect of VFDs. This course reviews the main types of VFDs available today. The course explains the principles of operation and the role of each component of the drive system and is designed to provide an understanding of the technologies involved with modern electric drive systems. The course covers motors, converters, control, load characteristics, energy efficiency, vibration issues, complete drive systems, large scale drives and their power factor and harmonics effects on the power plant grid

Target Audience: The course is intended for engineers and specialized technical staff involved with the specification, operation, and management of installations employing rotating machines, motors and electric drives, and those working with power station auxiliaries and electric power generation and power system quality. The topics in the course will enable participants to achieve stability, and efficient energy performance in their plants. The course will also be valuable for personnel who are dealing with drive installations, energy efficiency, power factor and harmonics issues.

Course Content

- Principles of AC Induction Motors

- Methods of reducing starting current

- Methods of achieving a variable speed drive

- Practical Star connection of 3 phase Motors.

- Practical Delta connection of 3 phase Motors.

- Practical Star-Delta connection of 3 phase Motors with manual and automatic starter.

- Inverter Theory

- Practical connection of motors and inverters

- Practical programming of inverters using a parameter unit

- Practical keypad, terminal and network connection and operation of motors and inverters

- Practical assessment to test knowledge and understanding

- Hardware Description

- Inverter Control with Terminal, OP, Modbus.

- POT(Potentiometer) connection diagram.

- Motor Speed Control with POT.

- Motor speed control with analog calibrator

- Motor speed control with load cell module.

- Motor on-off, Forward-Reverse and Speed control with PLC.

- Motor Trouble Shooting.

- Tricks & Tips

Job opportunities: VFD Service Engineer, VFD Commissioning Engineer, Executive Electrical Maintenance, Automation Engineer, Electrical Technician, Factory Manager, Instrumentation Engineer, Site Electrical Engineer, and Sales Engineer – Industrial Automation are some of the jobs available in this domain.

HMI(Human Machine Interface) Course Outline

HMI/Touch Screen Design

Course Objectives: Modern industrial plants rely heavily on HMI, generally driven at PLCs. Engineers dealing with HMI must be well trained to be able to operate, run, troubleshoot and understand of HMI. This course reviews designing HMI for industry.

Target Audience: The course is intended for engineers and specialized technical staff involved with the specification, operation, and management of installations employing machine, and those working with power station auxiliaries and electric power generation and power system quality. The topics in the course will enable participants to achieve stability, and efficient energy performance in their plants. The course will also be valuable for personnel who are dealing with automation system.

- Introduction to HMI

- Hardware Description

- Configuration between HMI and PLC.

- New window creation & linking.

- Button creation and design.

- Numeric Scaling & Demonstration.

- Output design.

- Multi-state word lamps and switches.

- Alarm Creation.

- Admin and User Role creation and security assigned.

- Log creation and monitoring.

- Trend Graph.

- Controlling field devices.

- Tricks & Tips